Starfield compound fabricators are machines utilized for producing complex items through the manipulation of matter on an atomic scale. Their versatility encompasses the fabrication of structures, devices, and even biological organisms, rendering them invaluable in various fields.

The significance of starfield compound fabricators lies in their unparalleled precision and efficiency. They eliminate the need for manual labor and traditional manufacturing processes, resulting in reduced production time and enhanced product quality. Moreover, these fabricators can operate autonomously, continuously producing goods without human intervention, leading to increased productivity and cost-effectiveness.

The historical context of starfield compound fabricators dates back to the early 21st century, when advancements in nanotechnology and materials science paved the way for their development. Since then, they have revolutionized industries ranging from aerospace and healthcare to energy and construction.

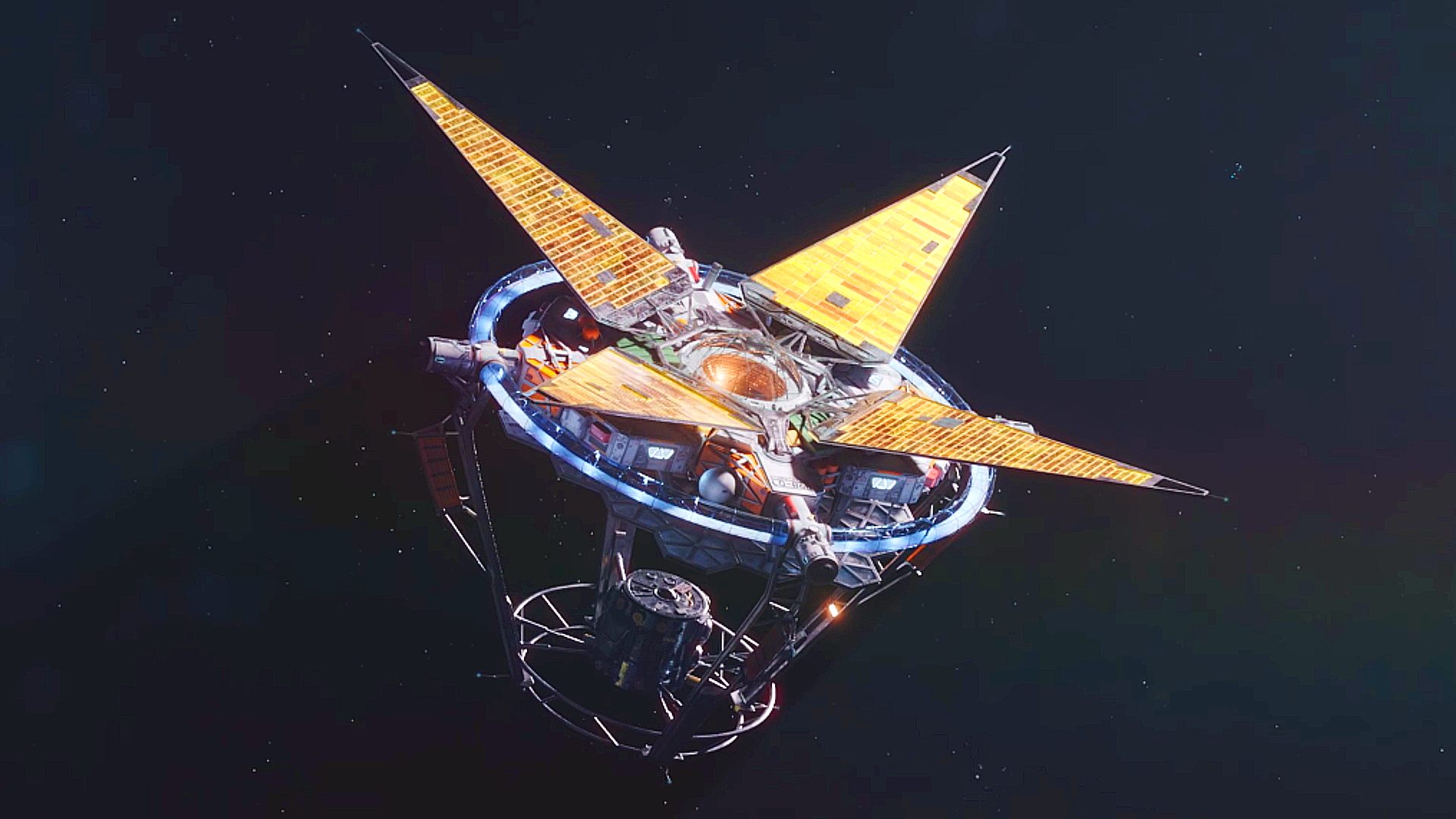

Starfield Compound Fabricator

Starfield compound fabricators are versatile machines capable of producing complex items through atomic-level matter manipulation. Their key aspects encompass:

- Precision Fabrication: Unmatched accuracy in creating intricate structures and devices.

- Material Versatility: Ability to work with a wide range of materials, including metals, ceramics, and biological matter.

- Automated Operation: Continuous production without human intervention, enhancing productivity.

- Customization: Tailored production of goods based on specific requirements.

- Sustainability: Environmentally friendly manufacturing processes, reducing waste and emissions.

- Nanotechnology Integration: Utilization of advanced nanotechnology for precise manipulation of matter.

- Research and Development: Pivotal role in scientific research and the development of innovative materials.

- Industrial Applications:.

These key aspects highlight the significance of starfield compound fabricators in modern manufacturing and technological advancements. Their ability to produce complex and customized goods efficiently and sustainably positions them as essential tools for industries seeking to innovate and meet the demands of the future.

Precision Fabrication

Precision fabrication, a defining characteristic of starfield compound fabricators, enables the creation of intricate structures and devices with unparalleled accuracy. This capability stems from the fabricator's ability to manipulate matter at the atomic level, allowing for the precise placement and arrangement of individual atoms and molecules.

The importance of precision fabrication in starfield compound fabricators cannot be overstated. It allows for the production of complex and delicate components that would be impossible to create using traditional manufacturing techniques. For instance, starfield compound fabricators are used to produce microfluidic devices for medical diagnostics, intricate sensors for aerospace applications, and high-performance electronic components for cutting-edge technologies.

The practical significance of precision fabrication extends beyond the creation of individual components. It also enables the fabrication of complete systems and assemblies with integrated functionality. This capability is particularly valuable in industries such as robotics, where complex mechanisms and devices require precise coordination and movement. By leveraging precision fabrication, starfield compound fabricators can produce robots with enhanced dexterity, precision, and reliability.

In summary, precision fabrication is a fundamental aspect of starfield compound fabricators that enables the creation of intricate structures and devices with unmatched accuracy. This capability drives innovation across a wide range of industries, fromand aerospace to robotics and electronics.

Material Versatility

The material versatility of starfield compound fabricators is a key factor that sets them apart from traditional manufacturing technologies. Their ability to work with a wide range of materials, including metals, ceramics, and biological matter, opens up a vast array of possibilities for innovation and the creation of new products.

One of the most important aspects of material versatility is the ability to combine different materials within a single fabricated object. This enables the creation of composite materials with unique properties that are not achievable using traditional manufacturing techniques. For example, starfield compound fabricators can be used to create materials that are both strong and lightweight, or that have high electrical conductivity and thermal insulation properties.

Another important aspect of material versatility is the ability to work with biological matter. This opens up the possibility of creating new types of medical devices and implants that are more compatible with the human body. For example, starfield compound fabricators are being used to develop new tissue engineering techniques that could help to repair damaged organs and tissues.

The material versatility of starfield compound fabricators is a key enabler for innovation in a wide range of industries, including aerospace, healthcare, and energy. By allowing the creation of new materials with unique properties, starfield compound fabricators are helping to drive the development of new technologies and products that will benefit society in the years to come.

Automated Operation

Automated operation is a key feature of starfield compound fabricators that enables continuous production without human intervention, leading to enhanced productivity.

- Uninterrupted Production: Starfield compound fabricators can operate 24/7 without the need for human operators, maximizing production capacity and minimizing downtime.

- Reduced Labor Costs: Automation eliminates the need for manual labor, significantly reducing labor costs and freeing up human workers for more complex tasks.

- Increased Efficiency: Automated operation ensures consistent and precise production, minimizing errors and waste, and improving overall efficiency.

- Scalability: Automated starfield compound fabricators can be easily scaled up to meet increased production demands, enabling businesses to respond quickly to market needs.

The automated operation of starfield compound fabricators brings numerous benefits, including reduced costs, increased efficiency, and improved scalability. These benefits make starfield compound fabricators an essential tool for businesses looking to streamline their production processes and gain a competitive edge in the market.

Customization

In the realm of manufacturing, customization holds immense significance, empowering businesses to cater to the unique needs of their customers. Starfield compound fabricators excel in this aspect, offering unparalleled capabilities for tailored production of goods based on specific requirements.

- Mass Customization: Starfield compound fabricators enable mass customization, allowing businesses to produce goods that are tailored to individual customer preferences. This opens up new avenues for businesses to differentiate their products and meet the diverse needs of consumers.

- Rapid Prototyping: The rapid prototyping capabilities of starfield compound fabricators accelerate the product development process. Designers can quickly create physical prototypes, iterate on designs, and bring customized products to market faster.

- Complex Geometries: Starfield compound fabricators can produce goods with complex geometries that are difficult or impossible to achieve using traditional manufacturing methods. This enables the creation of innovative products with enhanced functionality and aesthetics.

- Reduced Time-to-Market: The automated and efficient nature of starfield compound fabricators reduces the time required to bring customized products to market. Businesses can respond quickly to changing customer demands and capitalize on market opportunities.

The customization capabilities of starfield compound fabricators are transforming the manufacturing landscape. Businesses can now offer tailored products that meet the specific needs of their customers, leading to increased customer satisfaction, loyalty, and competitive advantage.

Sustainability

Starfield compound fabricators are renowned for their environmentally friendly manufacturing processes, reducing waste and emissions, and contributing to a more sustainable future.

The sustainable nature of starfield compound fabricators stems from their ability to minimize material waste. Traditional manufacturing processes often generate significant amounts of scrap and byproducts. However, starfield compound fabricators utilize advanced techniques to precisely control material usage, reducing waste and conserving resources.

Furthermore, starfield compound fabricators are designed to minimize energy consumption. They operate efficiently, reducing greenhouse gas emissions and contributing to a cleaner environment. Their automated and streamlined processes eliminate the need for manual labor and minimize energy usage.

The sustainability of starfield compound fabricators is not only beneficial for the environment but also for businesses. By reducing waste and emissions, businesses can lower their operating costs and enhance their reputation as environmentally responsible organizations.

In conclusion, the sustainability of starfield compound fabricators is a key aspect that sets them apart from traditional manufacturing technologies. Their environmentally friendly processes, reduced waste, and energy efficiency contribute to a more sustainable future while providing businesses with cost-saving benefits.

Nanotechnology Integration

The integration of advanced nanotechnology plays a pivotal role in the functioning of starfield compound fabricators, enabling them to manipulate matter with unparalleled precision. Nanotechnology involves the manipulation of materials at the atomic and molecular scale, allowing for the creation of structures and devices with unique properties.

In starfield compound fabricators, nanotechnology is utilized in various ways. For instance, it enables the precise placement of atoms and molecules during the fabrication process, resulting in the creation of materials with customized properties. This level of control is crucial for producing high-performance materials used in cutting-edge technologies such as aerospace and electronics.

Furthermore, nanotechnology empowers starfield compound fabricators to manipulate matter at the nanoscale, enabling the creation of intricate structures and devices that would be impossible to achieve using traditional manufacturing techniques. This capability opens up new possibilities for innovation in fields such as medicine and biotechnology, where nanoscale devices can be used for targeted drug delivery and tissue engineering.

In summary, the integration of nanotechnology is a fundamental aspect of starfield compound fabricators, providing the ability to manipulate matter with extreme precision and create advanced materials and devices. This integration drives innovation across various industries and contributes to the development of groundbreaking technologies that shape the future.

Research and Development

Research and development (R&D) plays a pivotal role in the advancement of starfield compound fabricators and the development of innovative materials. It drives the exploration of new materials, processes, and applications, pushing the boundaries of what is possible with this transformative technology.

Starfield compound fabricators rely on cutting-edge materials to achieve their remarkable capabilities. R&D efforts are dedicated to discovering and developing new materials with enhanced properties, such as strength, durability, and thermal conductivity. These advancements enable the fabrication of high-performance components and devices that meet the demands of demanding applications.

For instance, in the aerospace industry, R&D has led to the development of lightweight and heat-resistant materials for aircraft components. In the medical field, R&D has resulted in the creation of biocompatible materials for implants and tissue engineering.

The practical significance of R&D in starfield compound fabricators extends beyond material development. It also drives the refinement of fabrication processes, leading to increased precision, efficiency, and reliability. R&D efforts focus on optimizing process parameters, developing new techniques, and integrating advanced technologies to enhance the overall performance of starfield compound fabricators.

In summary, R&D is an indispensable component of starfield compound fabricators, fueling innovation in materials and processes. It enables the creation of advanced materials with tailored properties and drives the continuous improvement of fabrication capabilities. This ongoing research and development pave the way for groundbreaking applications and transformative technologies that shape the future.

Industrial Applications

Starfield compound fabricators have found widespread applications in industries such as aerospace, healthcare, energy, and construction due to their unique capabilities and versatility. These industries heavily rely on advanced materials and precision manufacturing techniques to achieve high performance and reliability in their products and systems.

In the aerospace industry, starfield compound fabricators are utilized to produce lightweight and durable aircraft components, such as wings, fuselages, and engine parts. These components must meet stringent requirements for strength, weight, and temperature resistance to ensure the safety and efficiency of aircraft. Starfield compound fabricators enable the fabrication of complex geometries and intricate designs that would be difficult or impossible to achieve using traditional manufacturing methods.

Within the healthcare sector, starfield compound fabricators play a crucial role in the development of medical devices and implants. These devices require high precision and biocompatibility to ensure patient safety and effectiveness. Starfield compound fabricators can produce customized implants that match the patient's anatomy, as well as sensors and other medical components with intricate structures and precise dimensions.

In the energy industry, starfield compound fabricators are used to manufacture components for renewable energy systems, such as solar panels and wind turbines. These components must be lightweight, durable, and efficient to maximize energy production. Starfield compound fabricators can produce complex shapes and optimize material properties to enhance the performance and lifespan of these systems.

The construction industry also benefits from the capabilities of starfield compound fabricators. These fabricators can produce construction materials with enhanced properties, such as strength, durability, and insulation. This enables the creation of buildings and structures that are more resilient, energy-efficient, and aesthetically pleasing.

In summary, the industrial applications of starfield compound fabricators are vast and varied, spanning across aerospace, healthcare, energy, and construction. These fabricators provide unique capabilities for the production of advanced materials and complex components, driving innovation and progress in these critical industries.

Starfield Compound Fabricator FAQs

This section addresses frequently asked questions about starfield compound fabricators, providing concise and informative answers to clarify common concerns or misconceptions.

Question 1: What are the key advantages of using starfield compound fabricators compared to traditional manufacturing methods?

Answer: Starfield compound fabricators offer several key advantages over traditional manufacturing methods, including the ability to produce complex geometries with high precision, the utilization of a wide range of materials, automated operation for increased productivity, and the capability for mass customization to meet specific requirements.

Question 2: How do starfield compound fabricators contribute to sustainability in manufacturing?

Answer: Starfield compound fabricators promote sustainability by minimizing material waste through precise material usage, reducing energy consumption through efficient operation, and enabling the production of lightweight and durable components that contribute to energy efficiency in various applications.

Question 3: What role does nanotechnology play in the functioning of starfield compound fabricators?

Answer: Nanotechnology is integral to starfield compound fabricators, allowing for the precise manipulation of matter at the atomic and molecular scale. This enables the creation of materials with customized properties, the fabrication of intricate structures and devices, and the development of advanced materials for cutting-edge technologies.

Question 4: How are starfield compound fabricators utilized in the aerospace industry?

Answer: In the aerospace industry, starfield compound fabricators are employed to manufacture lightweight and durable aircraft components, such as wings, fuselages, and engine parts. These components require high strength, weight optimization, and temperature resistance, which can be achieved through the precision and material versatility offered by starfield compound fabricators.

Question 5: What are the applications of starfield compound fabricators in the healthcare sector?

Answer: Starfield compound fabricators play a crucial role in the healthcare sector by enabling the production of medical devices and implants with high precision and biocompatibility. These devices can be customized to match patient anatomy, and the fabrication of intricate sensors and components contributes to the development of advanced medical technologies.

Question 6: How do starfield compound fabricators contribute to the energy industry?

Answer: In the energy industry, starfield compound fabricators are utilized to manufacture components for renewable energy systems, such as solar panels and wind turbines. These components require lightweight, durability, and efficiency to maximize energy production. Starfield compound fabricators enable the production of complex shapes and the optimization of material properties to enhance the performance and lifespan of these systems.

In summary, starfield compound fabricators offer a unique set of capabilities that address the demands of modern manufacturing, enabling the production of advanced materials and complex components with high precision, efficiency, and sustainability. Their applications span a wide range of industries, driving innovation and progress in fields such as aerospace, healthcare, energy, and construction.

Transition to the next article section: [Insert text here]

Tips for Utilizing Starfield Compound Fabricators

Starfield compound fabricators offer a transformative approach to manufacturing, enabling the production of advanced materials and complex components with unparalleled precision and efficiency. To leverage the full potential of these fabricators, consider the following tips:

Choose the Right Materials: The material versatility of starfield compound fabricators allows for a wide range of materials to be utilized. Carefully select materials based on the specific requirements of your application, considering factors such as strength, weight, and durability.

Optimize Design for Fabrication: Design your components with the capabilities of starfield compound fabricators in mind. Utilize complex geometries and consider the integration of multiple materials to enhance the functionality and performance of your products.

Leverage Automation: Starfield compound fabricators excel in automated operation. Take advantage of this capability to increase productivity, reduce labor costs, and ensure consistent quality in your manufacturing processes.

Explore Customization Options: Mass customization is a key strength of starfield compound fabricators. Utilize this capability to tailor products to specific customer requirements, enabling personalized and unique solutions.

Maintain and Calibrate Regularly: Proper maintenance and calibration are crucial for the optimal performance of starfield compound fabricators. Establish regular maintenance schedules and invest in calibration tools to ensure accuracy and longevity of your equipment.

By following these tips, you can effectively harness the capabilities of starfield compound fabricators, driving innovation and achieving exceptional results in your manufacturing operations.

Conclusion: Starfield compound fabricators represent a paradigm shift in manufacturing technology. By embracing their unique capabilities and implementing these tips, businesses can unlock new possibilities, enhance product quality, and gain a competitive edge in the modern manufacturing landscape.

Conclusion

Starfield compound fabricators embody a transformative force in the manufacturing landscape. Their ability to manipulate matter at the atomic level, combined with advanced automation and customization capabilities, opens up a realm of possibilities for innovation and technological advancements.

As we delve deeper into the applications of starfield compound fabricators, we witness their profound impact across diverse industries, including aerospace, healthcare, energy, and construction. These fabricators empower manufacturers to produce complex and high-performance components with unprecedented precision, efficiency, and sustainability.

The future holds even greater promise as starfield compound fabricators continue to evolve. Ongoing research and development efforts will further enhance their capabilities, enabling the creation of materials and devices that push the boundaries of what is currently possible. By embracing this transformative technology, we pave the way for a future where manufacturing is redefined by innovation, precision, and limitless possibilities.

Unravel The Secrets: Your "778 Angel Number Twin Flame" Journey Revealed

Unravel The Secrets Of Armpit Crossword Clues: A Journey Of Discovery

Unlock The Gates Of Excellence: Discover West Vancouver Academy Prep

ncG1vNJzZmianayFb63MrGpnnJmctrWty6ianpmeqL2ir8SsZZynnWTAta3Rn6CepJRisLC5z6isp5xdm66jvsicmK2nomO1tbnL